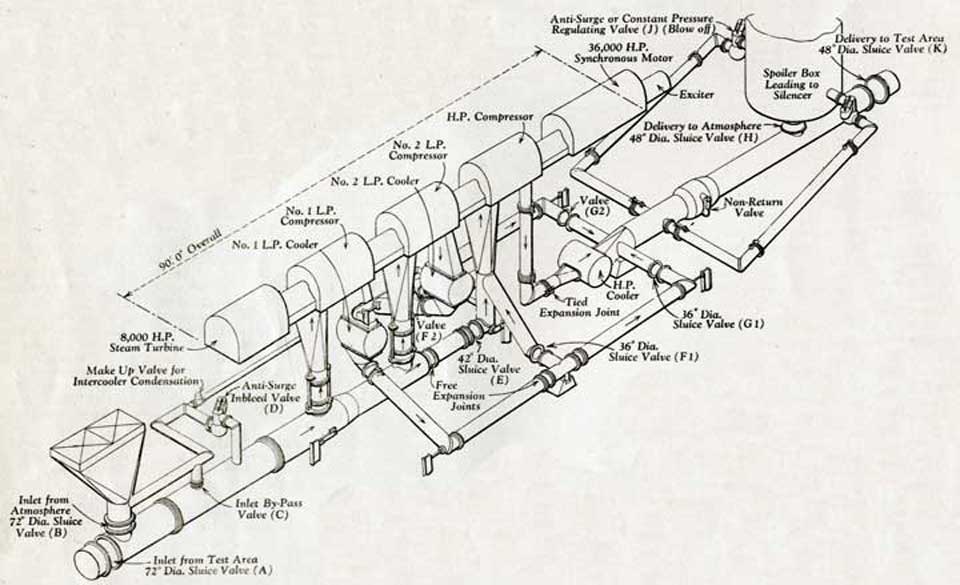

“There are eight identical units installed in the Air House, each unit consisting of an in-line

arrangement of an 8,000 h.p steam turbine, two low-pressure compressors, a high pressure compressor

and a 36,000 h.p. motor. The eight units aggregate to 352,000 h.p. believed to be the biggest

compressor installation of its kind in the western world.

The principal function of the steam turbine is to start the set, but it may also continue to give

power after the motor is synchronised and will in fact be required to do so when the set is

operating as a 9 to 1 compressor. The largest power demand occurs during cold winter conditions when

the steam turbine is required to deliver about 6,000 h.p. The choice of drive was influenced to some

extent by the existence of steam supplies on the site. It is technically sound on its own merits

since it obviates the rather fearsome problems of independent geared starting motors and the heavy

current demands at starting. An induction-motor drive would present power-factor difficulties at low

loads (exhausting duties) and such a machine would necessarily be of slow speed with very large

speed increasing gears. The civil-engineering cost for foundations and buildings would thus be

increased and the problem of high starting current would be present in acute form.”