The Air House came to N.G.T.E. in 1956 or thereabouts, there is no reference to it in site maps

dated May 1955 but there are references to its construction in papers dated September 1955. Those

papers refer to two existing air compressors each driven by 9,000 horsepower electric

motors and another driven by a 15,000 horsepower steam turbine and the need for “a facility for

testing ramjets and aircraft engines at high forward speed”. This was said to be “under

construction” and would be “supplied with compressed air from the Plant House and the Battle House”.

By December 1956, Hayne Constant, the then director of N.G.T.E. was writing in some detail about the

new engine test facility. He forecast that a test facility would include a 20 foot diameter ‘pod’

delivering air at 1,500 m.p.h. requiring 750,000 horsepower and at a cost of £100m. As is to be

expected, in the event, the initial installation fell a little short of that in some respects.

By the middle of 1957 it was being referred to in the past tense, effectively dating commissioning

of the Air House to 1956.

The Air House when initially commissioned boasted eight electrically driven compressors each of

44,000 horsepower, aided by a steam driven set of 36,000 horsepower. It could achieve air speeds of

2,000 m.p.h. There is no clear record of its eventual cost but its hourly operating cost was estimated (in

a paper dated 9 January 1959) to be £500 hour when compressing at maximum capability.

The air pipes were of seven feet diameter and diagrams of the air flows may be seen

here.

The electricity was supplied from a specially commissioned 275 megawatt substation in nearby Fleet.

Leslie Knight who

became the engineer in charge of the facility made regular visits to the national grid’s control

centre in East Grinstead to liaise with the Central Electricity Generating Board on when the

facility could be used. Some recollections of his time in the Air House and the effect of the large

electrical load on the local population may be read

here.

Some power was generated on site from the N.G.T.E.’s own experimental gas turbine (jet

engine) power station which was occasionally called upon to supply the

national grid, its rapid start up time being the main attraction to the C.E.G.B. However it wasn’t

anywhere near being capable

of meeting Pyestock’s own needs.

Air House cooling was by water obtained from the nearby Basingstoke Canal

and at one time the N.G.T.E. considered buying it from its owners when the latter were in financial difficulties.

Memory says that the asking price was £2,000 but the canal was instead taken over by the County Council.

The cooling system required a flow

of 500,000 gallons per hour. Presumably it was recycled but the notes do not say.

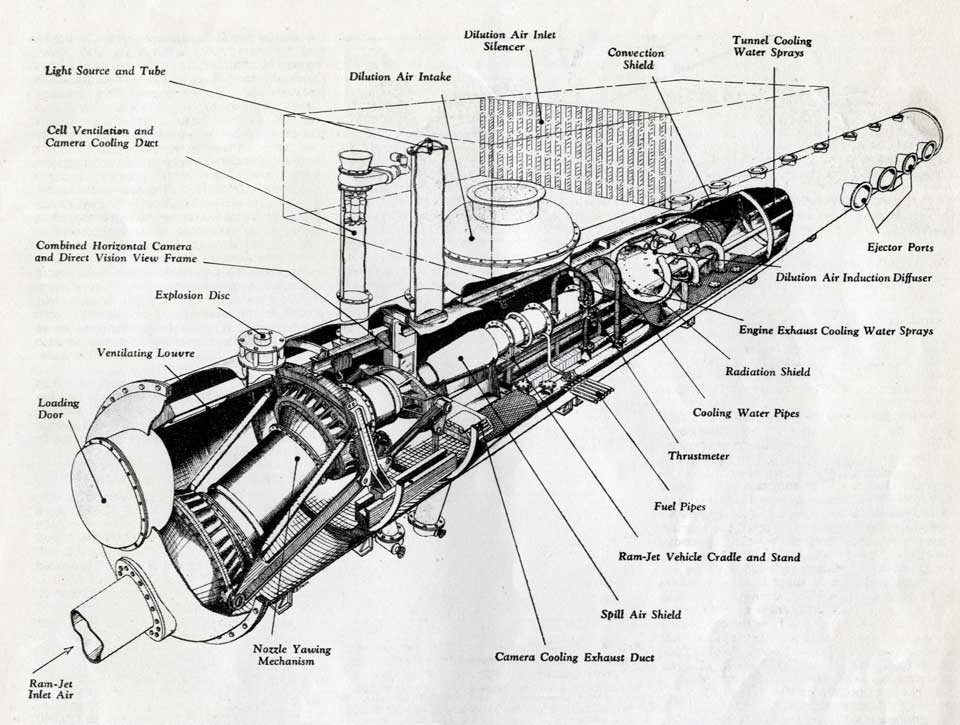

The ‘test pod’ (see diagram below) was monitored by “industrial television cameras”.

My recollection is that my father spoke of very nearly half a million horsepower being available in the Air

House but maybe that came about only after the

accident that severely damaged the facility causing it to be rebuilt.

Malcolm Knight

3 June 2007